Benefits of thermal wheels

The benefits of properly installed and maintained thermal wheels are significant, making them a frequently chosen option.

Advantages of thermal wheels:

- High-performance – recovery efficiency ranges from 73% to 85% (80% is optimal in the UK)

- Effective in varying climate conditions

- No need for condensate drainage

- Huge reduction in heating and cooling demand

- Humidity recovery while maintaining thermal comfort

- Wide range of industrial applications

- Reduction of ventilation and humidification costs

The potential drawback of thermal wheels is the mixing of incoming and outgoing air. This feature is what caused some confusion about the safety of using AHUs equipped with thermal wheels.

Do thermal wheels transmit bacteria and viruses?

The supply and extract airstreams of an AHU with a thermal wheel will always mix as the systems can never be completely sealed, and some degree of leakage between air streams is inevitable. This leakage occurs even when the rotor is switched off, so there is no benefit in deactivating the rotor if the fans are kept running for ventilation purposes.

However, as confirmed by the Federation of European Heating, Ventilation and Air Conditioning Associations (REHVA), when properly designed, constructed, installed and maintained thermal wheels “the leakage, from extract air potentially contaminated by pathogens to supply air stream, is typically very low and in practice negligible”. Similar opinions can be found in documents issued by other well-known organisations, e.g. the mentioned ECDC or the Chartered Institute of Building Services Engineers (CIBSE).

Is it better to use alternative solutions?

The leakage between air streams is inevitable in AHU constructions with thermal wheels and plate heat exchangers (PHE). CIBSE guide[ii] states that run-around coils (RAC) and plate heat exchange units keep the supply air and the extract air streams physically separate. Though this is true for RAC, there is always a risk of leakage from plate heat exchangers. According to current standards, a plate can have an internal leakage rate of up to 3%[iii]. For a Eurovent certified unit, this rate is reduced to 0.5%

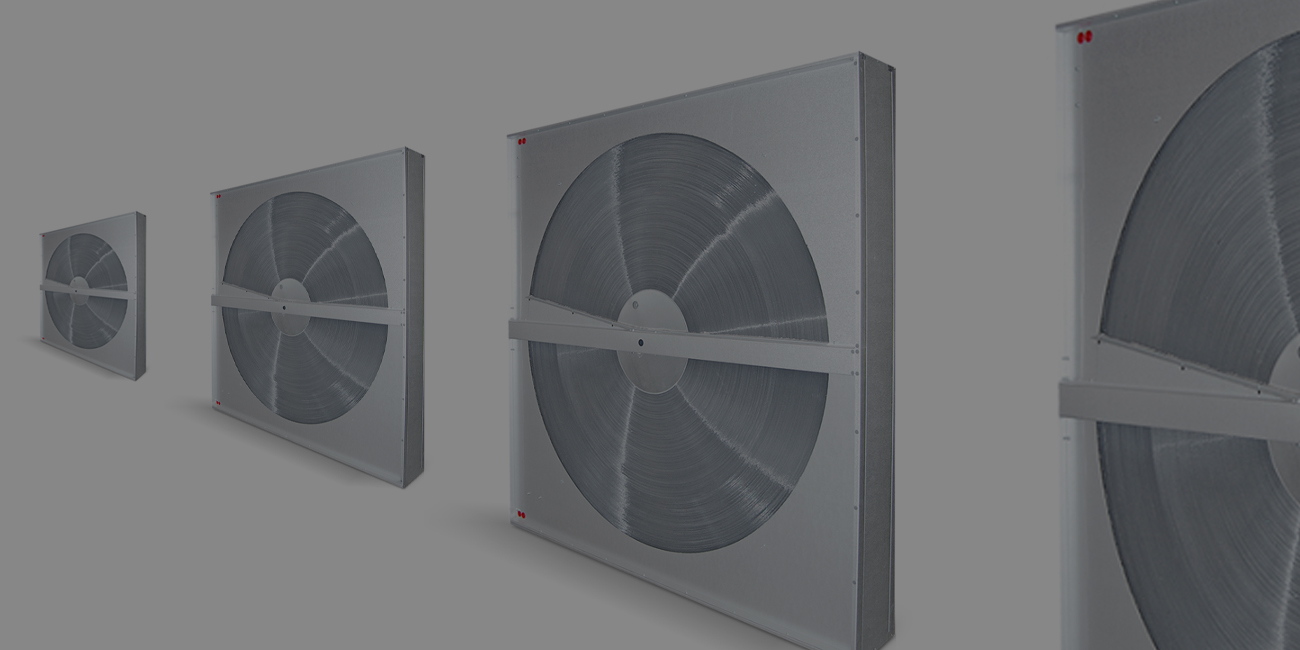

Still, due to the numerous advantages of thermal wheels, it is better to choose rotary units with leakage reduced to a minimum than to replace them with air handling units with other types of exchangers. FläktGroup has had such an offering available in our range since 2015, our AHU with Rotary Heat Exchanger and Automatic Pressure Balancing. With Automatic pressure balancing the leakage between extract and supply air is <1% and in practice close to zero. This is achieved by measuring and controlling the differential pressure between the extract and supply airstreams. The solution enlarges the scope for which thermal wheels can be used instead of PHE.

Want to know more about AHU & Rotary Heat Exchanger with Automatic Pressure Balancing? Contact us!

[i] ECDC - Heating, ventilation and air-conditioning systems in the context of COVID-19: first update 10 November 2020.

[ii] CIBSE - CIBSE COVID-19 VENTILATION GUIDANCE, Version 4. 23 October 2020.

[iii] prEN308 May 2020 - Heat exchangers - Test procedures for establishing performance of air to air and flue gases heat recovery devices.