- FläktGroup

- Solutions

- Gigafactory ventilation solutions

Gigafactory ventilation solutions

FläktGroup has a full range of ventilation and air treatment solution for battery production.

Gigafactories are at the heart of our renewable energy future

These factories are producing electric batteries on a huge scale, primarily for use in electric vehicles but also for a range of other renewable energy storage applications.

Correct ventilation is crucial in gigafactories to ensure a safe and healthy working environment. During construction, all parties should work together to ensure that high-quality ventilation systems are implemented, including the use of energy recovery systems for maximum efficiency

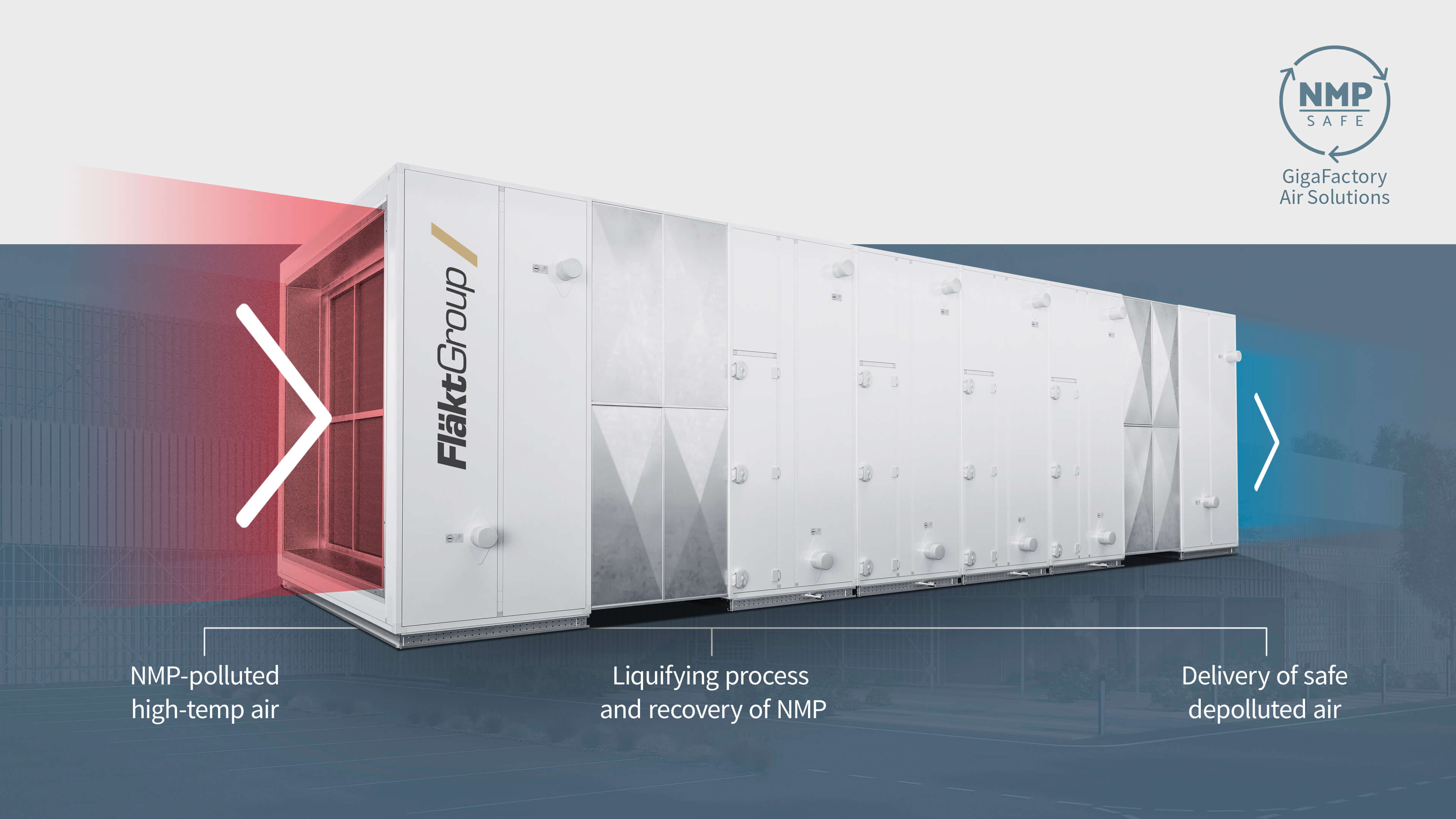

NMP - Safe Air Solutions for Gigafactories

FläktGroup has a full range of ventilation and air treatment solutions for battery production, not only to be used for the process with NMP, N-Méthyl-2-Pyrrolidon, recovery solutions, fresh air production equipment or dry room design and construction but also for all supporting facilities of the factory (such as office ventilation or computer room air conditioning).

FläktGroup has worked for decades to provide product solutions that manage air within hostile environments.

Our Process

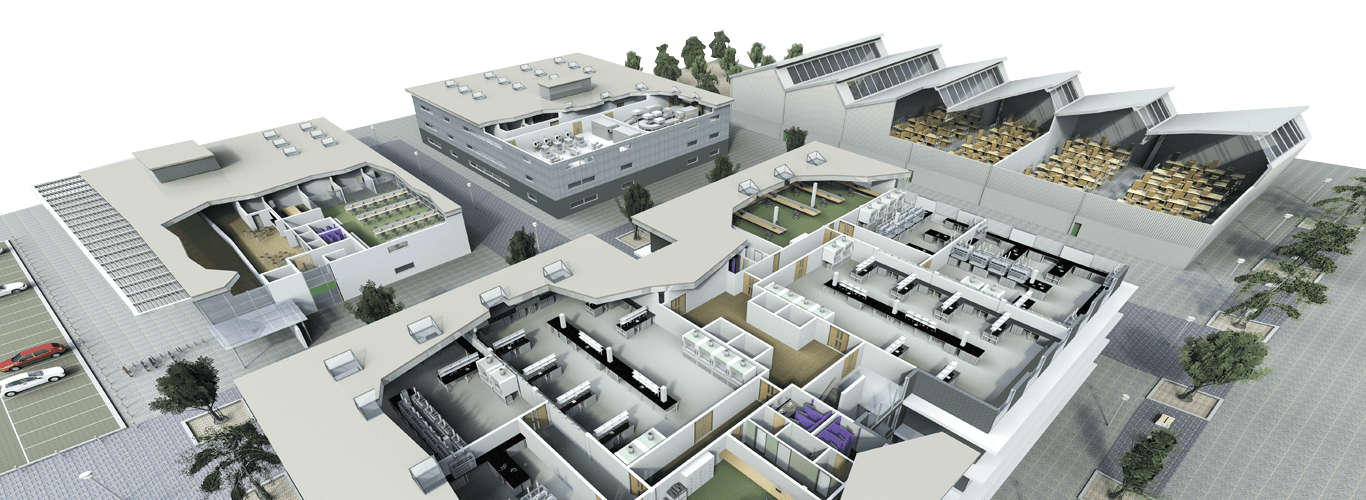

We offer a full portfolio of support every step of the way from 3D design to installation, to reports in order to develop your bespoke project.

1. Consultation

With decades of experience, we bring the necessary expertise into your project and help you to create an optimal concept for the Gigafactory, which is energy efficient and reliable.

2. Detailed Design

Once the Gigafactory layout is finalized, we create a 3D model with all little details – to the last screw.

For you to check – and for our production.

3. Production

All our factories work with the 5S approach and have a best-in-class on-time delivery rate.

In our modern facilities we produce fast standardized products, but are flexible to support you with customized solutions.

4. Installation

The installation is a crucial part in the process. Especially for a Gigafactory. Hence, we have very well trained teams in our core countries. Everywhere else, a supervisor from the factory will be present during the whole installation phase.

5. Validation

We support the finalization of your project by bringing in our long-term partners. You will get a full report, which is complying to all global and local regulations and standards. And – of course – you can be ensured, that your Gigafactory ventilation solution will operate as required.

Gigafactory Products

-

CAIRplus AIR HANDLING UNIT

CAIRplus AIR HANDLING UNIT

- CAIRplus is the tailor-made premium range of modular air handling units for every customer requirement

- Environmentally-friendly design means an energy recovery system with high efficiency is available for every configuration

- Clean surfaces and ease of cleaning guarantee hygienic standards to VDI6022

- All units can be supplied with FläktGroup integrated controls ISYteq 4.0

- T2/TB2/L1/D1 Eurovent certified casing

-

eQ MASTER® AIR HANDLING UNIT

eQ MASTER® AIR HANDLING UNIT

- Tailor made for customer needs

- Energy Efficient and optimized with integrated control

- Large variety of high efficiency components

-

eQL® AIR HANDLING UNIT

eQL® AIR HANDLING UNIT

- High degree of flexibility of functionality, configuration and materials

- Flexible and high efficiency energy recovery systems

- Optional service corridor

-

CEILINGS

CEILINGS

- LS ceiling – clip-in light ceiling

- KS ceiling – grid cassette ceiling

- KSH ceiling – walkable Alucore grid ceiling

- RS ceiling – walkable sandwich panel ceiling.

- A minimum number of particles is released from the panel surface

- Ease of installation, cleaning and sanitation, resistance to conventional disinfectants

- Joints between cassettes are sealed using permanently elastic sealant

-

Inwall FACINGS

Inwall FACINGS

- The ideal solution for adapting existing rooms into clean rooms.

- Easy and quick fixation to structural walls

- All panels are prefabricated – minimal adjustments on site

- All joints sealed with silicone

- Panels connected via conductive cables are grounded to the earthing point

-

DOORS & WINDOWS

DOORS & WINDOWS

- An automatic drop-down seal integrated into the door leaf enhances the air-tightness of a door

- Being flush with sandwich wall partitions ensures easy maintenance and flawless disinfection

- An interlock system equipped with signaling units prevents both doors in an airlock room from being opened simultaneously, effectively reducing the risk of contamination

- Doors can be opened manually or automatically with automatic drive

- Transfer doors are used as partitions of transfer boxes (passive or with filtered airflow)

- Accessories available include automatic drives, door closers, mirrors, windows with sunblinds, windows made from float glass or safety glass (ESG, VSG), automatic drop-down seals, stainless-steel kick plates, electromechanical and electromagnetic locks, signaling panels (semaphore), and many more.

-

EXHAUST-AIR COMPONENTS

EXHAUST-AIR COMPONENTS

- Reliable ventilation of anesthetic gases, particles and exhaust of room air burdened with microbes

- Various choices of extract-air components

- Seamless integration of extract-air components in all types of wall panels and facings

-

Fresh Breeze – FAN FILTER UNIT

Fresh Breeze – FAN FILTER UNIT

- Full area filtration

- Energy efficiency is ensured through EC fans

- Own production of HEPA and ULPA filters to perfectly match unit design

- Low initial pressure drop of filters

- Various air-outlet types

- Independent control unit

-

KTS SUPPLY AIR VALVE

Classic supply air valve

KTS SUPPLY AIR VALVE

Classic supply air valve -

RIS EXTERNAL LOUVRE

Robust square louvre for air intake and discharge

RIS EXTERNAL LOUVRE

Robust square louvre for air intake and discharge